Curing Compounds

Curing Compounds

Curing plays an important role on strength development and durability of concrete Properly cured concrete has an adequate amount of moisture within the body of it for continued hydration, which leads to strength development, volume stability, resistance to freezing and thawing, and resistance to abrasion and scaling. Even the

best quality concrete can fail if it is not cured properly_

Curing compounds are the solution where wet curing is impossible. These materials are applied by rollers, sprays, brushes etc onto wet concrete to act as membranes, which retard water evaporation during curing. Curing compounds reduce rapid volume change in the concrete, thus reducing shrinkage and maintain the specified strength requirements.

These are suitable for areas directly exposed to sunlight, heavy winds and other environmental influences. these can be used for curing of concrete pavements, airport runway, and bridge deck

Some popular uses are

• Concrete pavements,

• Airport runway, Bridge decks

• Precast concrete components

• Roof slabs, columns and beams.

• Chimneys, cooling towers

• High rise structures

Nirman Chemicals Limited offers the following Curing compound with high degree of curing efficiency:

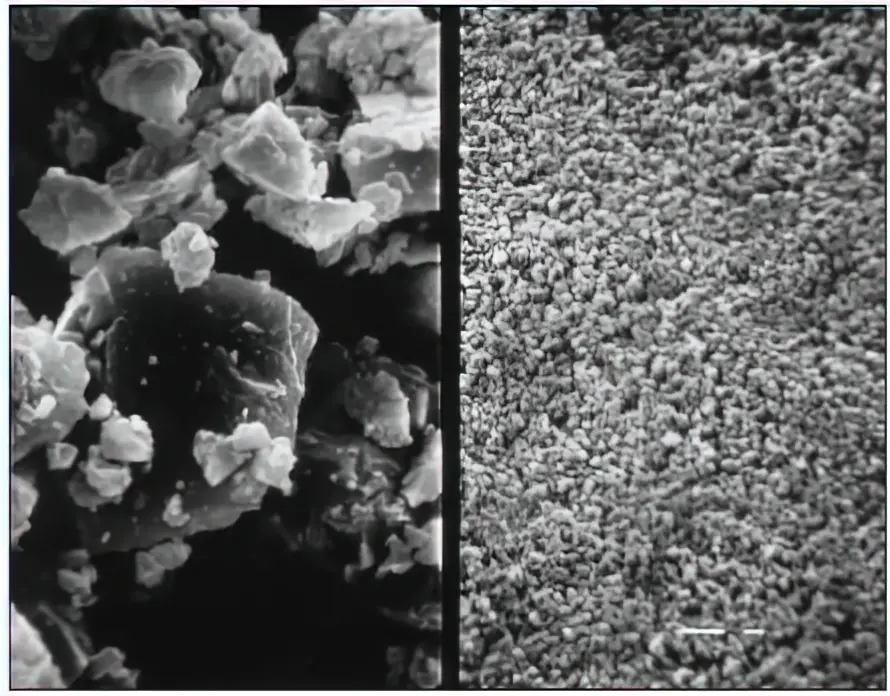

NIROCURE RB: It is a non-degrading. continuous film forming, aluminized, polymeric resin based curing compound, suitable for spray application on freshly poured concrete

NIROCURE RB is available as a silver-coloured liquid

The resultant film retains sufficient moisture within the concrete to ensure complete hydration of cement, essential for optimum strength development. The cured concrete is typically harder and exhibits a dust free surface with a reduced incidence of drying shrinkage cracks appearance.

Uses

A more effective and economical alternative to hessian and water and polythene curing regimes. Suitable for use on all types of large area concrete surfaces, such as airport runways, concrete roads and bridgeworks

Its application is restricted when subsequent renders, toppings or coatings are to be applied within the degradation time unless the curing compound is removed by proper cleaning.

NIROCURE RB has been tested in accordance with BS 7542- 1992 and the curing efficiency is greater than 90%

NIROClJRE WB: It is a white pigmented, membrane-forming, wax based curing compound, suitable for curing of newly placed or freshly de-shuttered concrete. It assists the retention of water during hydration.

The resultant film retains sufficient moisture within the concrete body to ensure complete hydration of cement, essential for optimum strength development. Membrane cured concrete is typically harder and exhibits a dust free surface with a reduced incidence of drying shrinkage cracks appearance.

Uses A more effective and economical alternative to hessian and water and polythene curing regimes. Suitable for use on all types of large area concrete surfaces, such as airport runwa ys, concrete roads and bridgeworks Its application is restricted when subsequent renders, toppings or coatings are to be applied within the degradation time unless the curing compound is removed by proper cleaning

NIROCURE WB complies to ASTM C309 Type II Class A BS 7542: 1992

NIROClJRE AB: It is a concrete curing compound based on a membrane forming acrylic emulsion in water. The material is liquid and sprayable on freshly poured concrete. The resultant film retains moisture within the concrete to ensure complete hydration of cement and helps the optimum strength development. Membrane cured concrete is typically harder and exhibits a dust free surface with a reduced incidence of drying shrinkage cracks appearance.

It is also suitable for use as a sealer and dust proofer for floors and walls. Particularly suitable for situations where after trades, such as paints or renders, are to be applied

The acrylic based concrete curing compound contains the property of adhesion to the succeeding plaster. lt is used to protect the concrete from the loss of water during

the initial time of curing

Uses

NIROCURE AB can be used in a wide range of applications, such as

- High rise construction to eliminate water curing

- Floors, warehouses, slabs and columns

- Dustproofing concrete walls and floors

- Clear sealer for concrete

- Self-curing, primer system to subsequent coverings

NIROCURE AB Complies to ASTM C309 Type l, class A and ASTM Cl31S