Eliminate vibration, enhance durability and shorten the Precast / Block production cycle

Precast / Block concrete is a form of concrete that is prepared, cast and cured off-site, usually in a

controlled factory environment, using reusable moulds. Precast / Block concrete elements can be joined to

other elements to form a complete structure. The precast / Block industry is driven by continually increasing of productivity with high quality concrete components that satisfy industrial and economical requirements. We are

offering our NIROCAST range of products to a wide range of markets of Precast / Block Industries, including components for buildings, civil engineering, drains, art stone, agriculture, roads and highways, railways and telecommunications. It can also be used in the casting of girders, prestressed floor support slabs, floor slabs, panels,

segments, pipes, different kind of blocks, vaults, cross-beams, faade units, paving and copings

The manufacture of Precast / Block concrete relies on quality constituent materials and the production process.

NIROCAST range of products now allow for the optimisation of:

- Rapid rotation of moulds

- Improved surface finish

- Early prestressing at low temperatures·

- Reduced energy consumption for heating or steam curing

- Reduced cement volume and use of replacement materials

- Accelerated strength development

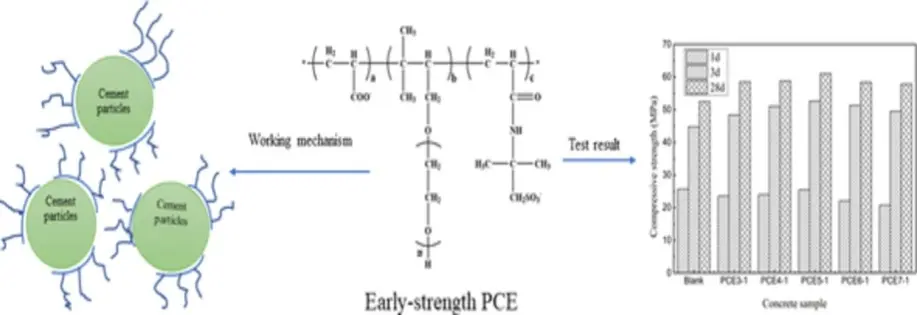

PCE molecules of NIROCAST range are rapidly adsorbed on the surface of the cement grains and disperse them through electrostatic and steric repulsion, as a result of this high dispersion , high flow/self compacting character developed in concrete which Minimises the Vibration process, Reduces the Energy Consumption and labour, and also enhances the durability of the concrete.

Unlike conventional PCE molecules, which cover the entire cement grain, the NIROCAST molecules progressive

adsorption leaves sufficient space on the cement surface to allow a rapid hydration. As a result of this effect. setting time/ de-moulding time of concrete become faster, which Increase the Productivity process in the precast

industries.

Due to faster hydration process, development of higher strengths at very early age of concrete become faster, and this advantage Minimise the heat curing process in the Precas/Block industries.

The NIROCAST SOE is suitable for all big precast / block elements

The NIROCAST 20E is suitable for all small precast /block elements